Test Details

Non-Destructive Inspection

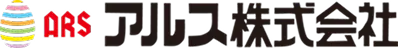

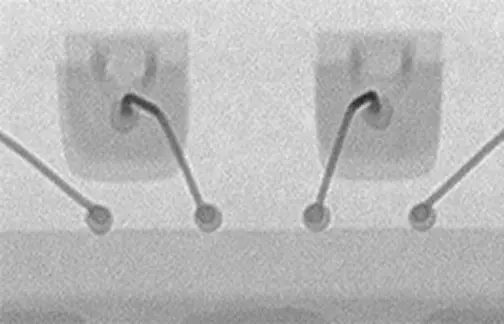

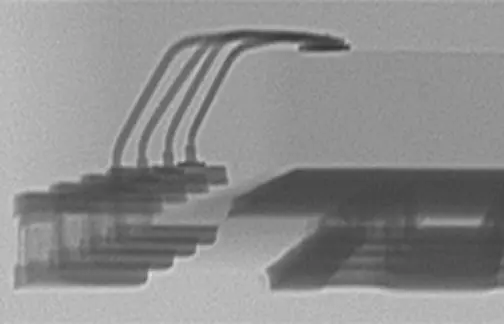

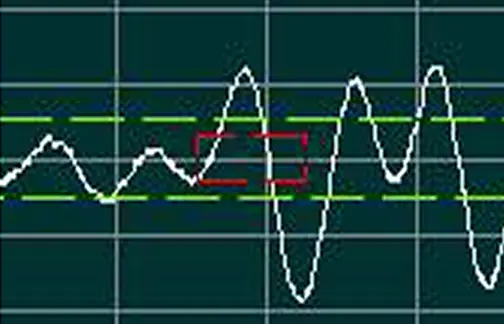

Internal structures are observed non-destructively by X-ray inspection and SAT (Scanning Acoustic Tomography).

- X-ray Inspection: Observes internal assembly structures to detect opens, shorts, and foreign materials.

- SAT (Scanning Acoustic Tomography): Observes internal bonding conditions to detect voids, cracks, and interfacial delamination.

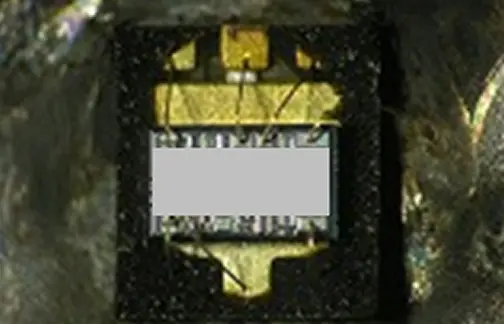

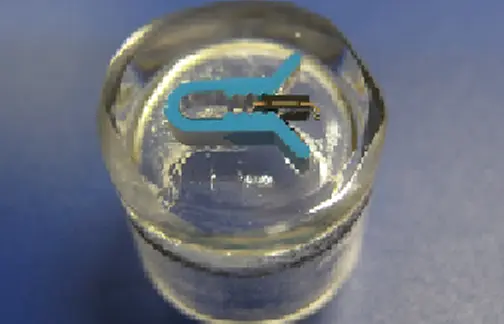

Package Decapsulation

Packages are opened using a combination of laser and chemical methods to minimize damage.

Internal observation is performed to identify chip cracks, wire breaks, and related failures.

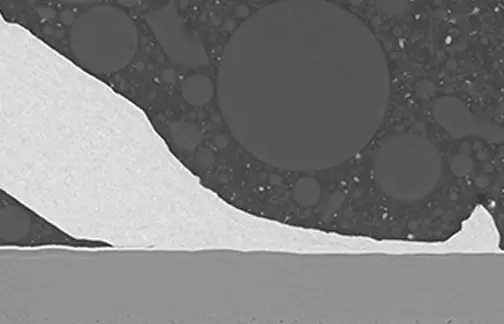

Cross-Sectional Analysis

Cross-sectional structures and bonding conditions are observed through mechanical polishing.

Delamination, intermetallic compound (IMC) layers, and wire neck breaks are evaluated.

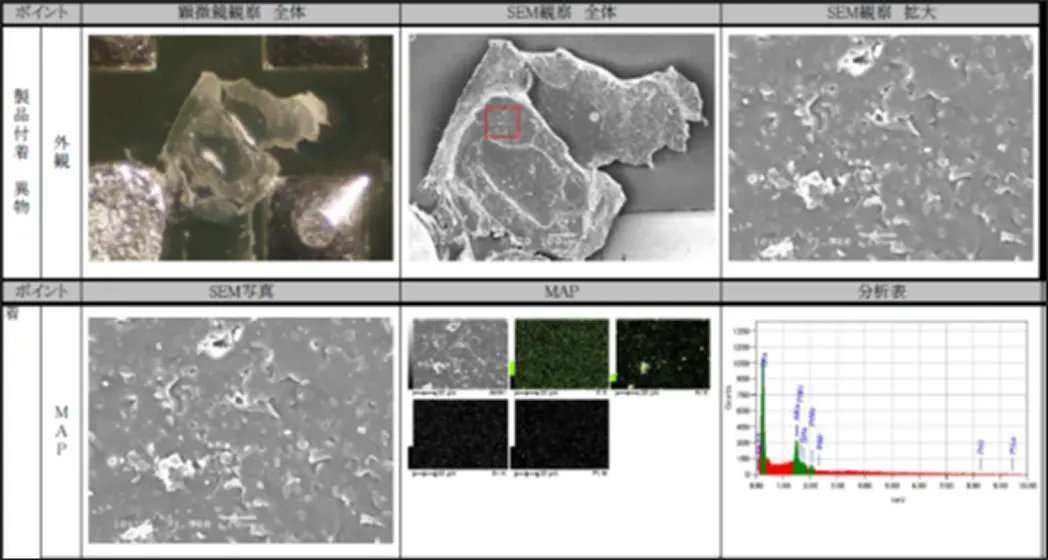

Foreign Material Analysis

Elemental analysis using EDS and material identification using FT-IR are performed.

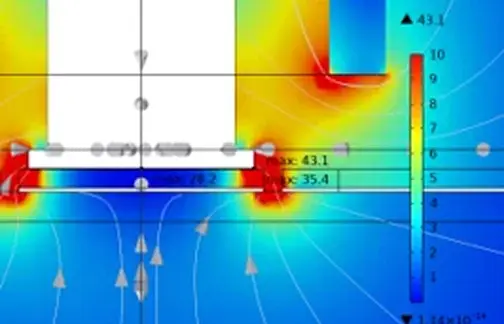

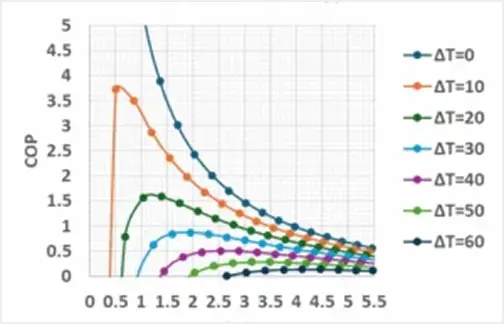

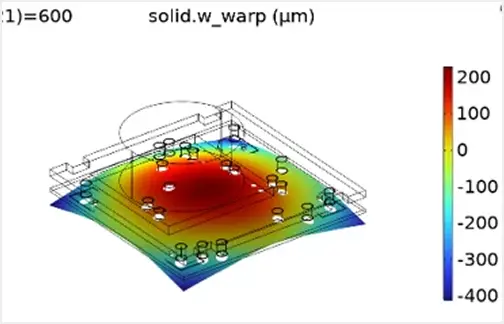

CAE (Simulation)

Thermal and structural analyses are conducted to predict and evaluate the following:

- Heat transfer (heat generation / cooling / thermal stress)

- Structural mechanics (stress / deformation / fracture / moisture absorption)

Equipment Details

| Equipment |

Details |

| Semiconductor Testers |

- Semiconductor testers (T7722, T2000, V93000, D10, etc.)

- Semiconductor parameter analyzers

|

| FT-IR Equipment |

- Fourier Transform Infrared Spectrometer (FT-IR)

|

| Visual / Failure Analysis Equipment |

- Digital microscope

- Scanning Electron Microscope (SEM)

- Electron Probe Micro Analyzer (EPMA)

|

| Emission / Thermal Observation |

|

| Others |

- Laser equipment

- X-ray inspection system

- Ion milling system

- Cross-sectioning equipment

- Ultrasonic imaging system

- Compact tabletop testing machine

- Plastic mold opener

- Die shear testing system

|

Please feel free to contact us for more information.